Explore the Diverse Applications of Seamless Steel Pipes

Seamless steel pipes are the backbone of countless industries where pressure, precision, and performance are critical. Unlike welded pipes, seamless pipes are manufactured without a weld seam, offering superior mechanical strength and a higher degree of corrosion and pressure resistance. Whether you're in energy, automotive, machinery, or chemical processing, choosing the right type of seamless steel pipe can greatly enhance your system’s safety and efficiency. Below, we break down the most common applications of seamless steel pipes—backed by data, industry standards, and real-world use cases—to help you make an informed decision. If you're not sure which pipe type fits your needs? Scroll down to explore—or simply contact our technical team for a one-on-one consultation.

Boiler Performance Tubes

Engineered for extreme heat and high-pressure conditions

_1751440168_WNo_900d600.jpg)

Precision Mechanical Tubing

Designed for dimensional accuracy and machinability

_1751440210_WNo_900d600.jpg)

Thermal Transfer Solutions

Optimized for efficient heat exchange

_1751440194_WNo_900d600.jpg)

Ultra-Precise Tubing

For mission-critical motion systems

_1751440539_WNo_900d600.jpg)

High-Pressure Tubing

Built for demanding fluid power applications

Dexin Steel Tube (China) Co., Ltd

Professional Seamless Pipe Manufacturer

Product Advantages

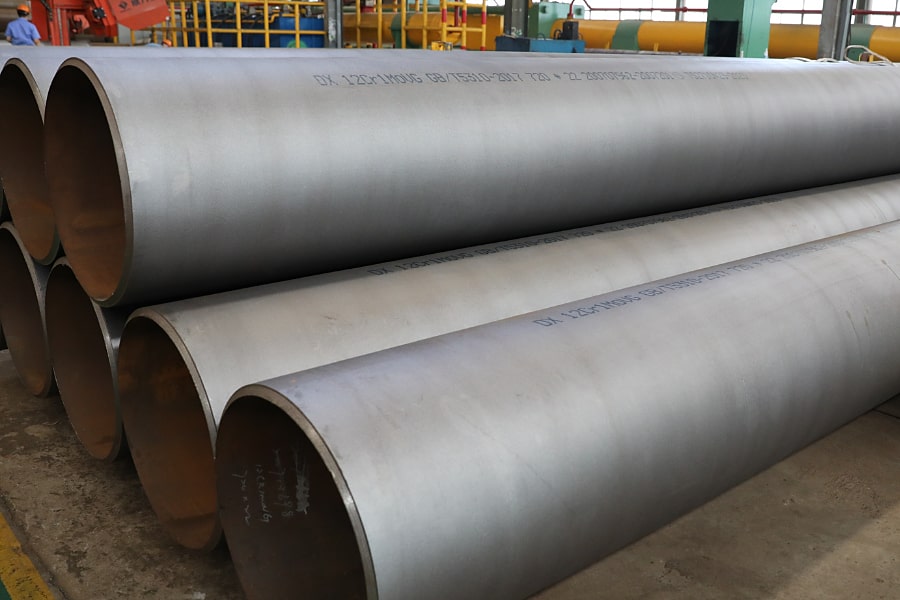

Specialized in large-diameter seamless pipes, maintaining 30,000 tons inventory covering carbon steel, alloy steel, stainless steel and more.

- Pipeline steel up to X80 grade

- Diameter below 1200mm

- Complete size range

- Fast delivery

Main Products

Professional production of various seamless pipes meeting high standards for petroleum, chemical, power and nuclear industries.

- Carbon steel pipes for pressure service

- Carbon steel pipes for high temperature

- Alloy steel boiler tubes

- Stainless steel pipes

- Steel pipes for low temperature

- Line pipes

Certifications

With complete quality management system, our products have safely operated over 100,000 hours with reliable quality.

- ISO 9001 Certified

- ISO 14001 Certified

- ISO 45001 Certified

- Sinopec Qualified Supplier

- CNPC Class A Supplier

-

Electric Power Field

Electric Power Field -

Petroleum Field

Petroleum Field -

Chemical Industry

Chemical Industry -

Storage

Storage -

Nuclear Power Field

Nuclear Power Field

-

Q1: What are the key differences between seamless and welded steel pipes?

Seamless pipes are produced without any welded seam, offering better strength, pressure resistance, and structural integrity than welded pipes. They're ideal for high-pressure, high-temperature, or critical environments such as boilers, oil pipelines, and hydraulic systems.

-

Q2: How do I choose the right seamless steel pipe for my application?

Consider factors like operating pressure and temperature, corrosion environment, material grade (carbon, alloy, stainless steel), wall thickness, and compliance with standards such as ASTM, EN, or API. For specific project needs, feel free to contact our technical team for personalized guidance.

-

Q3: What standards are commonly used for seamless steel pipes?

The most frequently used standards include ASTM A106/A53 (general purpose), ASTM A179/A213 (boiler and heat exchanger tubes), EN 10216-2 (pressure pipes), DIN 2391/EN 10305 (precision tubes), and API 5L/5CT (oil & gas industry).

-

Q4: Which steel grade is best for high-temperature or corrosive applications?

For high temperatures, grades like 15Mo3, T22, or SA213-T91 are recommended. For corrosive environments (e.g. chemical or marine), stainless steels like 316L or duplex alloys are more suitable. Material selection should match your media and conditions.

-

Q5: How do I verify the quality of seamless pipes before purchase?

Ask for mill test certificates (MTC), third-party inspections (SGS, BV), and NDT results (ultrasonic, eddy current, hydrostatic testing). Reputable manufacturers also comply with ISO, ASME, or API certification standards.

-

Q6: What is your typical lead time and delivery capability?

For in-stock items, delivery can be arranged in 3–7 days. Custom orders generally take 15–35 days depending on size, grade, and quantity. Our monthly capacity exceeds 30,000 tons, and we maintain over 30,000 tons of ready inventory for fast dispatch.

-

Q7: Can I request custom sizes, lengths, or finishes?

Absolutely. We offer cut-to-length, chamfered ends, honed bore, and special surface finishes such as phosphating or oiling. Just share your project drawings or specifications, and we’ll provide a tailored solution.

-

Q8: What’s the difference between hot-rolled and cold-drawn seamless pipes?

Hot-rolled pipes are produced at high temperatures, making them suitable for general structure and pressure piping. Cold-drawn pipes undergo further processing, resulting in tighter tolerances, better surface finish, and higher mechanical performance—ideal for precision and hydraulic applications.