Ever wondered how seamless pipes are made? The answer lies in a fascinating combination of engineering precision, advanced machinery, and meticulous craftsmanship. Unlike welded pipes, seamless pipes start as solid steel billets that are transformed into hollow tubes through carefully controlled processes.

From the intense heat of hot-rolling to the precise pulling of cold-drawing, every step in the manufacturing process affects the pipe’s strength, durability, and dimensional accuracy. In this article, we’ll take you deep into the seamless pipe production process, breaking down each production stage.

Table of Contents:

As the name suggests, a seamless pipe is a pipe without any weld seam. Instead of being joined from two edges, it is created from a solid piece of metal that's pierced and formed into a hollow tube.

Seamless pipes can be made from a variety of materials—most commonly carbon steel, stainless steel, and alloy steel. They come in different diameters and thicknesses, and depending on how they're manufactured, they can handle extreme conditions like high pressure, high temperature, or corrosive environments.

Now that we know what a seamless pipe is, the next big question is: how are seamless pipes made? The process isn't as simple as bending a piece of steel into a circle. Instead, it involves a series of precise steps that transform a solid round billet into a strong, hollow tube with no seams.

The manufacturing of seamless pipes generally follows two main routes:

Both methods produce seamless pipes, but each has its own unique role depending on the required pipe size, thickness, and application. Let's break them down.

Everything starts with a solid round steel billet (think of it like a chunky steel cylinder). These billets are usually cast from molten steel and cut to the right size for pipe making. Before forming, they're carefully heated in a furnace to make the steel more pliable.

This is the magic step where the pipe begins to take shape. The heated billet is pierced through the center using a piercing mill, creating a hollow "shell." This stage is critical, because it ensures that the pipe will have no weld seam—it's just one continuous piece of steel.

Once the hollow shell is formed, it goes through rolling mills. These machines elongate and reduce the thickness of the pipe while maintaining its round shape. Hot-rolling not only stretches the pipe but also helps achieve the desired diameter and wall thickness.

Sometimes, hot-rolling alone isn't enough—especially when high precision or smaller diameters are required. That's where cold drawing comes in. The hot-rolled pipe is cooled and then pulled (or "drawn") through a die and mandrel system. This reduces the pipe's diameter and wall thickness while improving its surface finish and dimensional accuracy.

After hot-rolling or cold-drawing, the pipes undergo heat treatment (like annealing or normalizing) to relieve internal stresses and improve mechanical strength. Then they're straightened, cut to size, and subjected to rigorous inspections, including ultrasonic testing, hydrostatic testing, and visual checks to ensure quality.

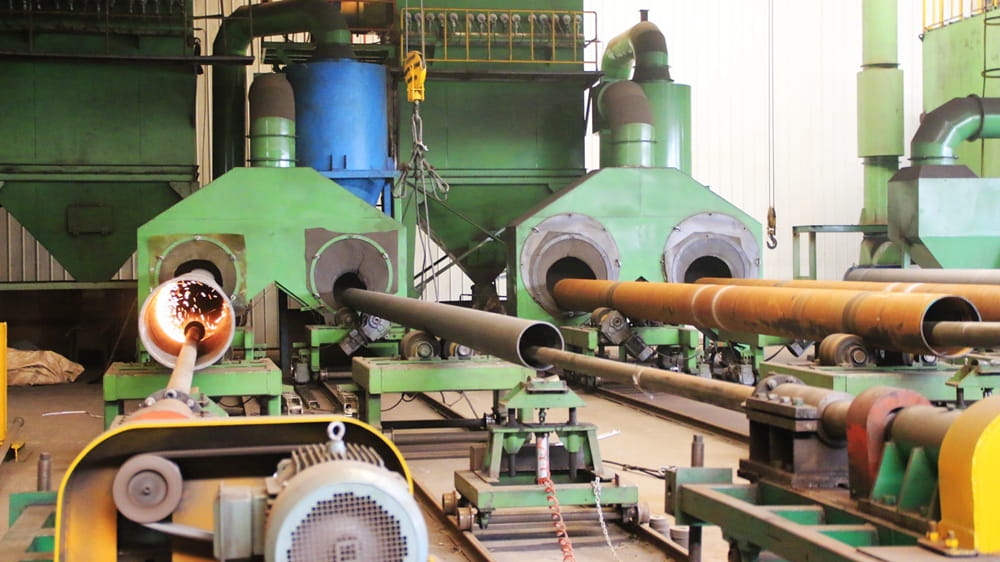

When people ask "how are seamless pipes made?", the hot-rolled process is usually the first answer. This method is one of the oldest and most widely used ways of producing seamless pipes. It's especially popular for creating large-diameter pipes with thick walls—the kind that must withstand high pressures in industries like oil & gas, power generation, and heavy machinery.

So, how exactly does the hot-rolled pipe manufacturing process work? Let's walk through it step by step.

Everything begins with a solid cylindrical steel billet. Imagine a thick steel log, cut to the right length. This billet is loaded into a rotary hearth furnace and heated to a red-hot temperature—typically above 1,200°C (2,200°F). At this stage, the steel is malleable, almost like clay, and ready to be formed.

Once the billet is glowing hot, it's fed into a piercing mill. Picture two powerful rollers pushing into the billet while a piercing plug drives through its center. This step transforms the solid billet into a hollow "shell" with no weld seam.

After piercing, the hollow shell isn't yet a finished pipe—it's rough, uneven, and too short. That's where rolling mills come in:

At this point, the hot-rolled seamless pipe starts to take its final shape.

For pipes that require specific diameters, the hot-rolled shell passes through a reducing mill. This fine-tunes the pipe dimensions, ensuring consistent roundness and wall thickness.

Once the hot-rolled pipe has been formed, it's left to cool on cooling beds. As steel cools, it may bend slightly, so the pipe goes through a straightening machine where rollers ensure a perfectly straight tube.

While the hot-rolled method is great for large sizes, sometimes industries need seamless pipes with smaller diameters, thinner walls, and tighter tolerances. That's where the cold-drawn pipe manufacturing process comes in. It's essentially the "precision version" of seamless pipe making.

Think of it this way: if hot-rolling is like shaping clay when it's soft and hot, cold-drawing is like carefully carving and polishing the hardened piece to get exact dimensions. For high-precision applications, see our guide on cold-drawn seamless pipes.

The process begins not with a solid billet, but with a hot-rolled hollow tube (sometimes called a mother tube). This tube has already gone through the piercing and rolling stages of hot production but isn't yet precise enough for high-performance applications.

Before drawing, the tube is pickled in acid to remove scale and impurities from its surface. Then, a special lubricant coating (like phosphate soap) is applied to reduce friction during drawing. This step ensures a smoother surface and prevents defects.

Here's the key step. The tube is pulled (or "drawn") through a die—a hard tool with a precisely machined opening. A mandrel or plug may also be inserted inside the tube to control internal diameter and wall thickness.

As the tube passes through the die:

This can be repeated several times, depending on how small or precise the pipe needs to be.

Cold working makes steel stronger but also harder and less ductile. To restore its workability, the tube is sometimes annealed (reheated and cooled under controlled conditions) between drawing passes. This balances strength and flexibility.

Once the pipe reaches its target dimensions, it's straightened with roller machines to ensure perfect alignment. Then it's cut into standard or custom lengths.

Cold-drawn pipes are often used in industries where precision is critical—like automotive, aerospace, boilers, and hydraulics—so quality control is strict. Tests may include:

Both the hot-rolled and cold-drawn seamless pipe manufacturing processes play a vital role in today's industries. Here's a side-by-side comparison to make the differences clear:

| Feature | Hot-Rolled Seamless Pipes | Cold-Drawn Seamless Pipes |

|---|---|---|

| Starting Material | Solid billet | Hot-rolled hollow tube (mother tube) |

| Manufacturing Temperature | High temperature (above 1,200°C / 2,200°F) | Room temperature (cold forming) |

| Main Process | Piercing, rolling, elongating, reducing | Drawing through a die, sometimes with a mandrel |

| Diameter Range | Larger diameters, thick walls | Smaller diameters, thin walls |

| Surface Finish | Rougher surface, needs finishing | Smooth, precise finish |

| Dimensional Accuracy | Moderate accuracy | High precision and tight tolerances |

| Strength | Good overall strength | Enhanced strength due to cold working |

| Applications | Oil & gas pipelines, boilers, structural components, heavy industry | Automotive, aerospace, hydraulics, heat exchangers, precision machinery |

| Cost Efficiency | More economical for larger pipes | Higher cost due to extra processing steps |

Hot-rolled seamless pipes are best suited for applications requiring large diameters, thick walls, and high strength. They are ideal for:

Recommendation: If you are designing large-scale industrial or pipeline projects, hot-rolled seamless pipes provide the durability and cost-efficiency you need. For example, they are perfect for long-distance oil and gas transmission where high pressure and temperature resistance are critical.

Cold-drawn seamless pipes offer high dimensional accuracy, smooth surface finish, and superior mechanical properties, making them ideal for:

Recommendation: If your project involves precision applications like hydraulic cylinders or machinery tubing, cold-drawn seamless pipes ensure tight tolerances and reliable performance under pressure.

Seamless pipes have become an irreplaceable part of modern industry. From the strength and durability of hot-rolled pipes to the precision and accuracy of cold-drawn pipes, each process offers unique advantages to meet specific needs. Whether it's heavy-duty pipelines in energy and construction, or high-precision tubing in automotive and aerospace, seamless steel pipes continue to prove their value where safety, reliability, and performance matter most.

That's why choosing the right manufacturing partner makes all the difference. Since 2002, Dexin has specialized in producing and supplying high-quality seamless steel pipes to customers worldwide. Our range includes large-diameter cold-drawn pipes, SCH 40 seamless pipes, SCH 80 pipes, and more. With advanced hot-rolled and cold-drawn production capabilities, we provide not only the pipes you need, but also the expertise and reliability to support your most demanding projects.

When strength, precision, and trust are what you're looking for, Dexin is here to deliver seamless solutions—built to last, made for your success.

Related similar content recommendations:

Seamless Steel Pipe Manufacturing Process

Seamless Steel Pipe Manufacturing Process - UNIASEN

How Seamless Carbon Steel Pipe Is Made

How is Seamless Pipe Made? - Reibus International

Seamless Pipe vs Welded Pipe – Key Differences

Uses of Seamless Pipes in Industry

Seamless Pipe Manufacturers in India

Your Name*

Your Email*