How is seamless steel pipe made? This is one of the first questions engineers, buyers, and project managers ask when selecting steel pipe for high-pressure or critical applications. The seamless steel pipe manufacturing process is fundamentally different from welded pipe production, as it forms the pipe from a solid steel billet without any welding seam. Each step—heating, piercing, rolling, sizing, and heat treatment—plays a direct role in determining the pipe’s strength, wall thickness consistency, pressure resistance, and overall service life. Understanding how seamless steel pipe is made helps buyers evaluate quality, compare suppliers, and choose the right pipe for oil & gas, power generation, mechanical, and industrial projects.

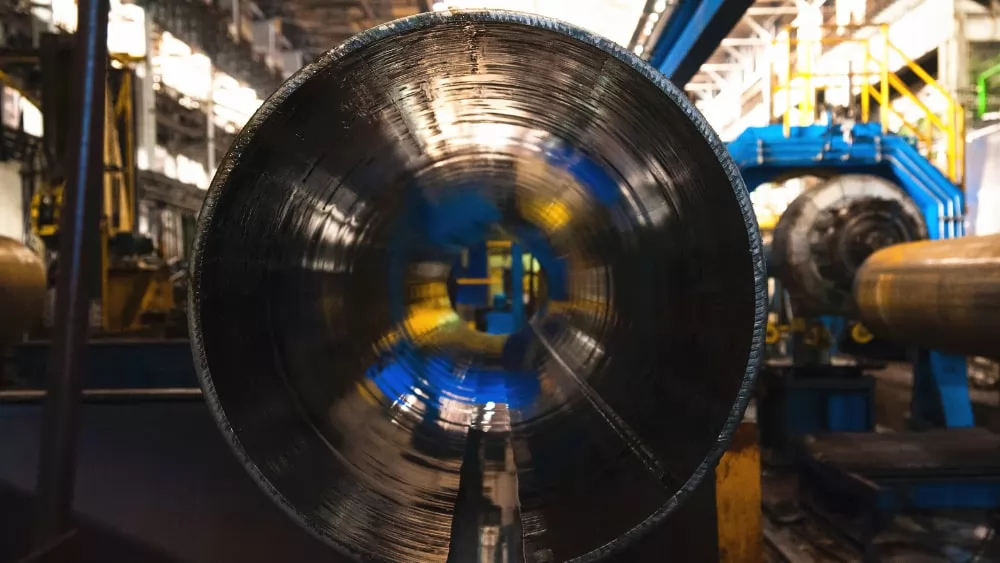

The hot rolled seamless pipe process utilizes round steel billets as the primary raw material. These billets are first heated to elevated temperatures (typically ranging from 1100 to 1250 degrees Celsius) within a rotary heating furnace. Subsequently, the heated billets are pierced into hollow billets using a piercing machine—for example, a cone-roller piercing machine or a pressure piercing machine. Following the piercing stage, the resulting hollow billets undergo further processing via a pipe rolling mill, such as an automatic pipe rolling mill, a continuous pipe rolling mill, an Assel pipe rolling mill, or an Accu-Roll pipe rolling mill. This rolling process serves to reduce the wall thickness and extend the length of the billets. The final step involves controlling the outer diameter precision through a sizing mill or a reducing mill, thereby yielding the finished seamless steel pipes.

Key Equipment: Rotary heating furnace, piercing machine, pipe rolling mill set (with the continuous pipe rolling mill set being the most commonly employed), sizing mill, straightening machine, and non-destructive testing equipment.

This process is commonly employed in the production of oil and gas transmission pipelines, boiler pipes, mechanical structural pipes, and fluid transportation pipes, where the requirements for precision and surface quality are not exceptionally stringent.

The cold drawn seamless pipe process utilizes rough pipes (or semi-finished pipes) derived from hot-rolled seamless pipes as the raw material. Initially, these pipes undergo pickling to eliminate surface oxide scales. Following the pickling stage, the pipes are drawn through a cold drawing machine—such as a chain-type cold drawing machine or a hydraulic cold drawing machine. During the drawing process, the steel pipe is pulled through a die hole (a fixed die), and under the influence of pulling force, it passes through a mandrel (or is drawn without a mandrel). This action reduces both the outer diameter and the wall thickness, effectively achieving the desired dimensional reductions. To attain the target specifications, multiple drawing passes (multiple stages) can be performed.

Key Equipment: Pickling tank, cold drawing machine, annealing furnace (utilized for intermediate annealing to soften the metal), and a lubrication device (designed to minimize drawing friction).

This process is predominantly used in the manufacturing of high-end precision components, including automotive half-shaft sleeves, hydraulic prop pipes, bearing pipes, high-pressure boiler pipes, and precision mechanical structural pipes.

The cold rolled seamless pipe process shares similarities with the cold drawn process; however, it substitutes "rolling" for "drawing." In this process, rough pipes are sleeved onto a long mandrel and fed into the rolls of a cold rolling mill—for instance, an LG-type cold rolling mill or an LD-type cold rolling mill. Through the rotation and applied pressure of the rolls, the steel pipe undergoes plastic deformation. Simultaneously, the mandrel restricts the inner wall, facilitating the reduction of both wall thickness and outer diameter. This process is frequently combined with cold drawing (forming a "cold rolling - cold drawing combined process") to enhance production efficiency and dimensional accuracy.

Key Equipment: Cold rolling mill (which demands high-precision rolls and mandrels), mandrel removal machine, and a lubrication system.

The cold rolled process is ideal for manufacturing aviation engine pipes, instrument pipes, medical device pipes, ultra-thin-walled heat exchanger pipes, and other ultra-precision applications.

The extrusion seamless pipe process involves placing a heated steel billet into an extrusion cylinder. By applying an immense pressure—ranging from 1000 to 3000 MPa—through an extrusion ram, the steel billet is compelled to extrude through a die hole, resulting in the formation of a seamless pipe. This process can be categorized into forward extrusion (where the movement direction of the billet and the resulting pipe is the same), reverse extrusion (where the movement directions are opposite), and hydrostatic extrusion (which utilizes high-pressure liquid to transmit the applied pressure).

Key Equipment: Extrusion press (such as a large hydraulic press or oil press), heating furnace, and a die (comprising a die hole and a mandrel).

The extrusion process is primarily employed in specialized material fields, such as aerospace titanium alloy pipes, nuclear power stainless steel pipes, high-temperature alloy pipes, and copper-nickel alloy pipes.

The push bench process utilizes solid round steel billets as the raw material. Within a press, a mandrel (core rod) is pushed into the heated steel billet from one end, creating a hollow billet (analogous to "drilling a hole"). Subsequent processes, such as diameter expansion and sizing, are then performed to achieve the final pipe dimensions. This process represents an older manufacturing technique and is progressively being supplanted by hot rolling methods.

Features: This process is considered an ancient technique and is gradually being replaced by hot rolling.

It is commonly used for manufacturing pipes intended for agricultural machinery and low-pressure applications, where the quality requirements are relatively lenient.

The spinning seamless pipe process involves securing a flat plate or pre-formed billet onto a spinning machine. Through the application of pressure from high-speed rotating cores and rollers, the billet undergoes point-by-point plastic deformation, ultimately forming a seamless pipe (or special-shaped pipe). This process is divided into ordinary spinning and hot spinning (where the billet is heated to reduce deformation resistance).

Features: This process is categorized into ordinary spinning and hot spinning (utilizing heated billets to reduce deformation resistance).

The spinning process is utilized in the manufacturing of specialized, custom-made components, including rocket engine nozzles, satellite antenna support pipes, high-end decorative pipes, and other tailored applications.

Dexin has always focused on producing and supplying high-quality seamless steel pipes to the global market. We offer one-stop solutions covering material selection, precision manufacturing, quality inspection, and export logistics. Our seamless steel pipes meet international standards such as ASTM, API, and EN, and are widely used in oil and gas, construction, machinery, boilers, and industrial piping systems.

Backed by advanced production lines, strict quality control systems, and experienced technical teams, Dexin is committed to helping customers reduce procurement risks, shorten lead times, and control costs—without compromising performance or reliability. Contact our professional team today to discuss your seamless steel pipe requirements and discover how Dexin can support your next project with stable supply and competitive pricing.

Your Name*

Your Email*