Seamless carbon steel pipes, commonly referred to as CS pipes, are steel tubes made without any welded seam. The term "CS" stands for Carbon Steel, which is steel where the main alloying element is carbon. Unlike welded pipes, seamless pipes are manufactured by extruding or rolling solid steel billets to form a hollow tube, resulting in a uniform structure and higher mechanical strength.

Seamless CS pipes are widely used in industries where strength, reliability, and pressure resistance are critical. Typical applications include:

For first-time buyers and new procurement teams, the biggest challenge in sourcing seamless carbon steel pipes is that many products look similar on paper but perform very differently in real applications. Pipes may be listed under the same standard, size, and grade, yet the actual manufacturing quality can vary significantly.

These differences are rarely obvious during the buying stage. A pipe that appears compliant in specifications may still suffer from inconsistent wall thickness or unstable mechanical performance, directly affecting pressure resistance and service life. New buyers who rely mainly on datasheets and price comparisons are the most likely to encounter this gap between stated information and real performance.

For beginners, choosing the right seamless CS pipe is therefore less about selecting a standard and more about understanding how manufacturing quality determines whether the pipe will perform safely and reliably over time.

For first-time buyers, assessing seamless carbon steel pipe quality does not require advanced metallurgical knowledge, but it does require attention to several measurable and verifiable factors. The following quality checks are widely used in real procurement and inspection processes and have a direct impact on safety and service life.

Wall thickness consistency is the most critical factor affecting pressure resistance. According to common standards such as ASTM A106 and API 5L, wall thickness tolerance is usually controlled within ±12.5%. Pipes that fall outside this range may experience reduced burst pressure and uneven stress distribution. Buyers should request actual measurement data or inspection reports rather than relying only on nominal wall thickness values.

Seamless carbon steel pipes must meet defined chemical composition and mechanical property requirements, including yield strength, tensile strength, and elongation. For example, ASTM A106 Grade B typically requires a minimum yield strength of around 240 MPa. Verifying these values through a mill test certificate (MTC) helps confirm that the pipe material matches the stated grade and intended application.

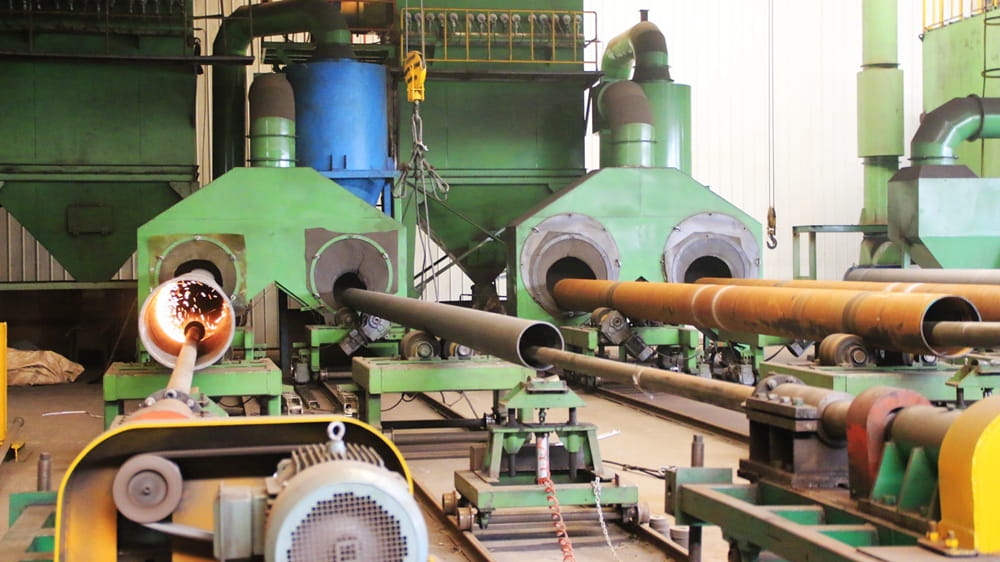

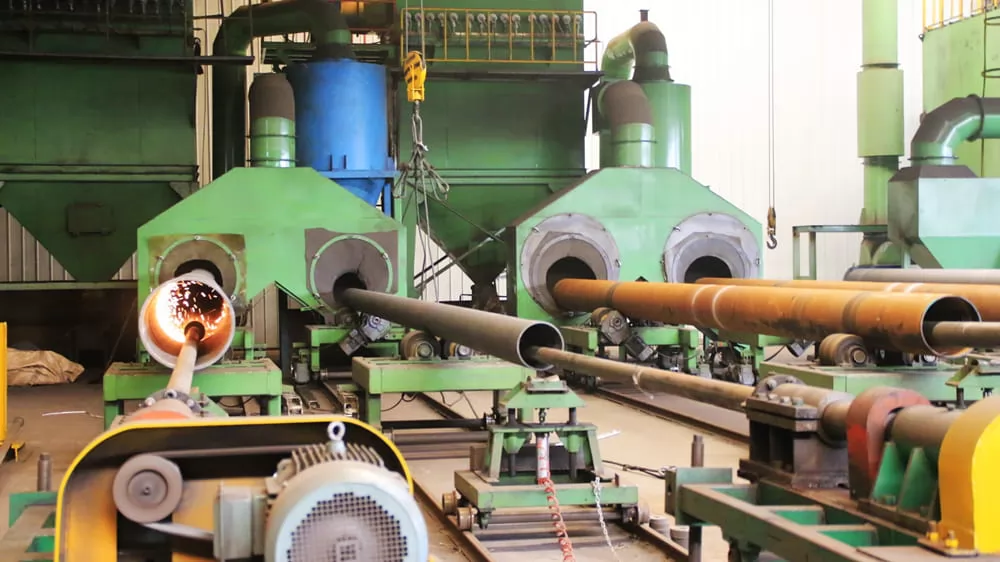

Manufacturing process control directly affects internal structure and performance. Seamless pipes are commonly produced through hot rolling or cold drawing, followed by heat treatment such as normalizing. Proper heat treatment improves grain structure uniformity and mechanical stability, reducing the risk of brittle behavior or localized weakness.

Surface condition offers practical clues about overall quality. Defects such as longitudinal cracks, laminations, or heavy scale may indicate process instability. In many industrial applications, pipes are also subject to non-destructive testing (NDT) methods such as ultrasonic testing (UT) or eddy current testing (ECT) to detect internal flaws that are not visible externally.

By focusing on these measurable quality factors, beginner buyers can evaluate seamless carbon steel pipes using objective criteria rather than price alone, reducing technical risk and improving long-term reliability.

For first-time buyers of seamless carbon steel pipes, understanding key standards and certifications is essential to ensure safety and long-term reliability. These documents provide verified evidence that the pipe meets chemical, mechanical, and dimensional requirements, reducing the risk of purchasing substandard products.

An MTC is the most critical document for every seamless pipe purchase. It confirms the pipe’s chemical composition, tensile strength, yield strength, and elongation. For example, ASTM A106 Grade B pipes require a minimum yield strength of 240 MPa and a tensile strength between 415–550 MPa. Reviewing the MTC ensures that the material matches the stated grade and that the pipe is suitable for its intended pressure and temperature conditions.

Pipes are often manufactured according to standards such as ASTM A106, ASTM A53, or API 5L. These standards define dimensional tolerances, wall thickness, chemical composition, and mechanical properties. Buyers should know the specific standard required for their application—for example, pressure pipelines versus structural uses—so they can verify that the pipe fully complies.

Some suppliers provide NDT reports, such as ultrasonic testing (UT) or eddy current testing (ECT), which confirm that the pipe is free of internal flaws like laminations or micro-cracks. While beginners may not perform these tests themselves, asking for NDT documentation adds an extra layer of confidence in critical applications.

Depending on the end-use and region, certifications such as ISO 9001 (quality management) or PED (Pressure Equipment Directive for European applications) may be required. These certifications indicate that the supplier follows standardized quality management practices and that their processes are regularly audited.

By checking these key documents and standards, new buyers can verify the authenticity, quality, and compliance of seamless carbon steel pipes without needing deep technical expertise. This approach helps avoid costly mistakes and ensures that the selected pipes perform reliably in their intended applications.

For first-time buyers, the biggest challenge isn’t just understanding specifications—it’s navigating a market full of suppliers, quotes, and conflicting information. Here are the most common mistakes that often waste time, money, or lead to unsuitable purchases.

Many beginners trust supplier descriptions without verification. Claims like “ASTM A106 Grade B compliant” or “fully tested” are often taken at face value. The risk: receiving pipes that do not meet your pressure or temperature requirements. Tip: Always ask for original mill test certificates (MTCs) and cross-check supplier references before ordering.

It’s tempting to choose the lowest price, but beginners often ignore shipping costs, delivery time, and lead time variability. A pipe arriving late or damaged can disrupt your schedule and raise costs. Tip: Evaluate total procurement time and supplier reliability alongside unit price.

Beginners often select pipes based on size and standard alone, without considering actual operating conditions such as pressure, temperature, or corrosive environment. This can lead to pipes failing sooner than expected. Tip: Make a simple checklist of your project conditions and confirm the supplier can provide pipes rated for your specific use.

Receiving pipes without proper inspection is a common time-wasting mistake. Pipes may have dents, rust, or handling damage during transport. Tip: Schedule visual inspections or request third-party inspection for critical orders to avoid surprises upon arrival.

Beginners sometimes choose suppliers who are slow to respond or provide vague information. Poor communication can delay decisions, cause misunderstandings about specs, or result in incorrect orders. Tip: Prioritize suppliers who provide clear documentation, quick responses, and technical support to guide your purchase.

By being aware of these real-world mistakes, first-time buyers can save time, reduce procurement risk, and ensure that the seamless CS pipes they select truly match their project needs.

Several well-known global manufacturers specialize in high-quality seamless carbon steel pipes, ensuring compliance with international standards such as ASTM, API, and EN. Some of the leading names include:

Understanding what CS pipes are, their main applications, and the reputable suppliers can help first-time buyers make more informed decisions and avoid common pitfalls when sourcing seamless carbon steel pipes.

In summary, identifying a good seamless carbon steel pipe requires focusing on the most critical checks: wall thickness consistency, verified material grade, proper manufacturing processes, and reliable supplier credentials. These key checks help ensure the pipe performs safely under pressure, meets project requirements, and avoids costly failures.

For first-time buyers, taking the time to request mill test certificates, review standard compliance, inspect surface quality, and evaluate supplier reliability can save both time and money. By following these practical steps, you can confidently select seamless CS pipes that are not only durable but also suitable for your specific application.

Remember, a high-quality seamless carbon steel pipe is a reflection of both the material and the supplier. Prioritizing these key checks will help you make informed purchasing decisions and achieve long-term reliability in your projects.

Your Name*

Your Email*