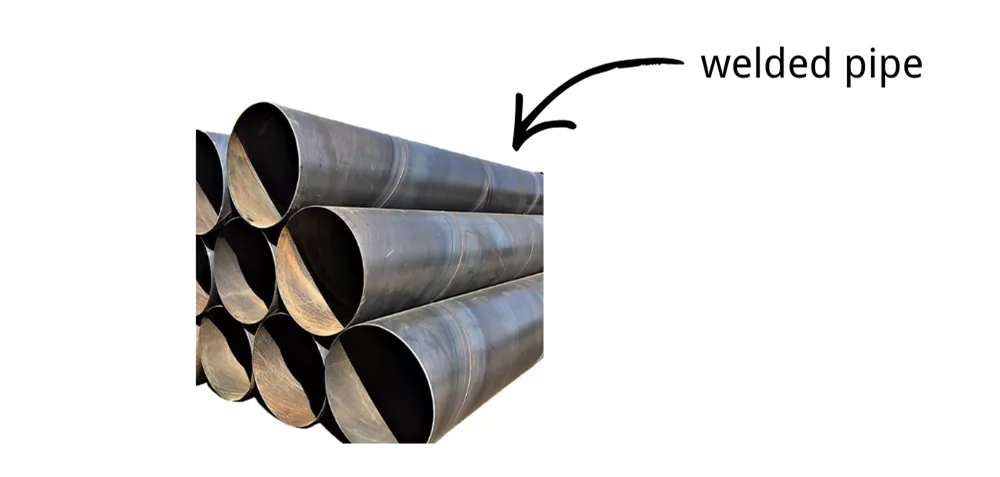

If you've ever wondered how to identify seamless pipe — whether you're inspecting materials on-site, selecting suppliers, or verifying product quality — you're not alone. Seamless pipes look deceptively similar to welded pipes at first glance, yet their lack of a weld seam makes them stronger, more reliable, and suited for high-pressure or critical applications.

Don't worry, identifying seamless pipe isn't a skill only professionals can master. Through this guide, you will learn a simple, practical, and step-by-step identification method, from basic visual observation to practical field techniques, allowing even beginners to make accurate judgments in minutes.

Simply put, seamless pipe is a complete metal tube without any joints from beginning to end. It's like a hollow tube drilled from a solid metal rod, rather than being made by rolling and welding sheet metal.

If you are new to steel pipe procurement or engineering material acceptance, facing a pile of visually similar steel pipes, you may wonder: "How to distinguish whether it is a seamless steel pipe?" In fact, as long as you master 4 basic and practical identification methods, even beginners can quickly judge—the key lies in "whether there is a weld" and "manufacturing process characteristics." The following 4 methods, from naked-eye observation to simple tool assistance, help you get started easily!

Core Logic: Seamless steel pipes are integrally formed through perforation, hot rolling, or cold drawing processes, theoretically having no longitudinal welds; while welded pipes (such as ERW welded pipes, submerged arc welded pipes) are made by curling steel plates/strips and then welding them together, inevitably having a continuous weld line.

Operation Steps:

Core Logic: During the welding process of welded pipes, the metal thickness in the weld area is usually slightly thicker (due to welding filler material) or thinner (due to heat-affected zone contraction) than the base material, resulting in uneven wall thickness distribution along the entire pipe; while seamless steel pipes are formed by rolling or drawing, with smaller wall thickness deviation and overall more uniformity.

Operation Steps:

Core Logic: The metal structure of seamless steel pipes is continuous and dense, so when tapped, the sound is crisper, louder, and has a metallic echo; welded pipes, due to welding defects (such as pores, incomplete fusion) at the weld, or material differences between the weld and base material, produce a duller, shorter sound when tapped, and even local "puffing" sounds.

Operation Steps:

Core Logic: Seamless steel pipes produced by regular manufacturers will mark the implementation standard (such as GB/T 8162, ASTM A106), material (such as 20# steel, 304 stainless steel), and specification (outer diameter × wall thickness) on the pipe body or packaging, and attach a material test certificate (MTC) or quality certificate, clearly indicating "seamless pipe" and production process; while welded pipes usually only mark "welded steel pipe" or specific welding methods (such as ERW).

Operation Steps:

For beginners, start with "observing weld traces" and "measuring wall thickness uniformity" (naked eye + simple tools can operate), then combine with "tapping to listen" for auxiliary judgment, and finally confirm official information through "markings and certificates." Remember the key points: seamless pipes have no welds, uniform wall thickness, and traceable materials—master these 4 methods, and you can easily avoid the pitfall of "buying welded pipes as seamless pipes"!

If you need to purchase seamless steel pipes, you can choose to contact us. We are a professional seamless pipe manufacturer with professional experience and can provide you with service and support!

Your Name*

Your Email*