If you're new to piping materials, construction, or industrial supplies, you've probably encountered the term "galvanized seamless steel pipe" and are wondering what it means, what it's used for, and why it's important. Don't worry, you're not alone. Many beginners get confused by this kind of technical terminology at first. This guide will explain the definition and common uses of galvanized seamless steel pipe in a simple and easy-to-understand way, even if you don't have a professional background.

Galvanized seamless steel pipe is a seamless steel tube that has been treated with a zinc coating through a hot-dip or electro-galvanizing process, to improve corrosion resistance and service life.

Main advantages

Because of these combined advantages, galvanized seamless steel pipes are commonly used in water supply systems, oil and gas transportation, fire protection pipelines, and various industrial and construction applications where strength and long service life are essential.

Galvanized seamless steel pipes can be classified into hot-dip galvanized seamless steel pipes and electro-galvanized seamless steel pipes according to their manufacturing process. This is the most fundamental classification method, determining the corrosion resistance and cost of the steel pipe.

Seamless steel pipes are immersed in molten zinc, forming an alloy layer through a physicochemical reaction. This is currently the mainstream process, producing a thick zinc layer (typically 30-80 micrometers), strong adhesion, and a long corrosion resistance life (up to 20-50 years). It is suitable for demanding applications such as building structures, fire protection systems, and high-pressure fluid transportation.

A zinc layer is deposited on the surface of the steel pipe through electrolysis. The zinc layer is thinner (typically less than 15 micrometers), with a smooth surface. The cost is relatively higher, and it is mostly used for interior decoration or light industrial applications where a high degree of surface finish is required.

| Comparison Aspect | Ordinary Seamless Steel Pipe | Galvanized Seamless Steel Pipe |

|---|---|---|

| Definition | Seamless steel pipe produced through hot rolling or cold drawing processes. The surface is typically black or dark gray, commonly referred to as “black pipe”. | A finished product created by applying a zinc coating to the surface of ordinary seamless steel pipes. The surface usually appears silver-white. |

| Appearance | Metallic base color (gray-black) with a smooth surface or rolling marks. | Silver-white surface with metallic luster, often showing zinc crystal patterns (spangle). |

| Corrosion Resistance | Poor. Easily rusts when exposed to air, moisture, or corrosive environments and usually requires additional protective treatment such as painting. | Excellent. The zinc coating isolates air and moisture, providing both physical barrier protection and electrochemical protection (sacrificial anode), resulting in a longer service life. |

| Production Process | Piercing, rolling, sizing, and heat treatment. | Based on seamless pipe manufacturing, additional processes include pickling, fluxing, and hot-dip galvanizing. |

| Cost | Lower cost, mainly covering raw material and manufacturing expenses. | Higher cost due to additional galvanizing processing and zinc coating materials. |

| Main Applications | High-pressure fluid transportation (oil and gas), mechanical structural components, and boiler pipes requiring high temperature and pressure resistance. | Building water supply and drainage, fire sprinkler systems, gas transportation, and outdoor guardrails requiring corrosion resistance and aesthetic appearance. |

Ordinary seamless steel pipes usually have a gray-black surface caused by oxide scale or the original steel finish. The surface feels hard and metallic. Galvanized seamless steel pipes have a silver-white appearance with a bright metallic sheen. Hot-dip galvanized pipes may have a slightly rough surface or visible zinc spangle patterns, while electro-galvanized pipes usually have a smoother finish.

Ordinary seamless steel pipes have no protective coating. When exposed to moisture, salt spray, or acidic environments, they can rust quickly. This corrosion gradually reduces wall thickness and may eventually cause leakage or structural failure.

Galvanized seamless steel pipes provide dual corrosion protection:

Because of this dual protection, galvanized seamless steel pipes can last several times longer than ordinary seamless pipes in outdoor or humid environments.

Ordinary Seamless Steel Pipe Production:

Steel Billet → Heating → Piercing → Rolling → Sizing → Cooling → Finished Product

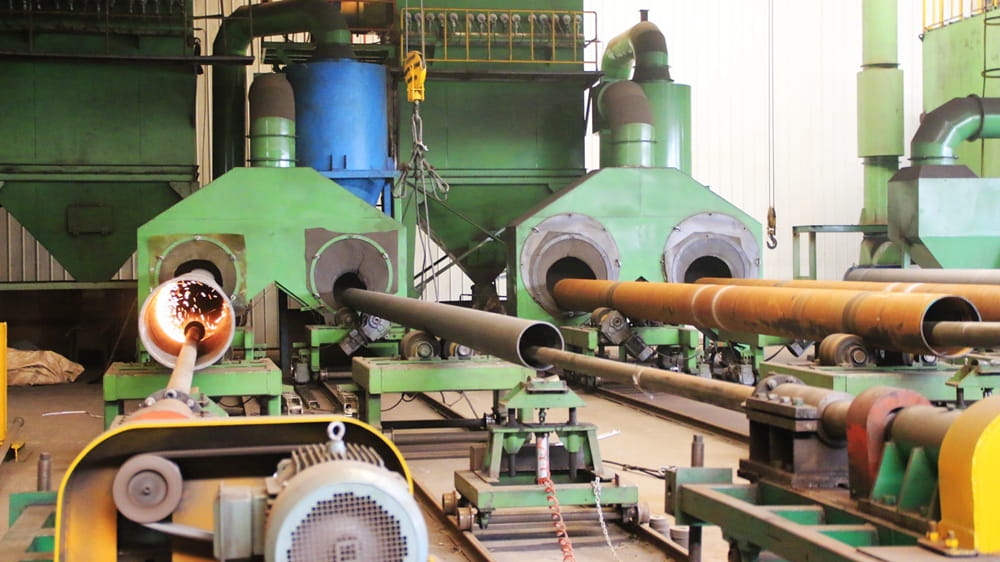

Galvanized Seamless Steel Pipe Production:

Ordinary Seamless Steel Pipe → Pickling (Rust Removal) → Fluxing (Oxidation Prevention) → Hot-Dip Galvanizing → Cooling → Finished Product

You should choose galvanized seamless steel pipes when your project requires both high structural strength and long-term corrosion protection. These pipes combine the pressure resistance of seamless steel with the anti-rust protection of a zinc coating, making them essential in specific applications and environments.

If steel pipes will be exposed to rain, humidity, or changing weather conditions, galvanized seamless steel pipes are highly recommended. The zinc coating protects the steel surface from rust and significantly extends the service life of the pipe, making it suitable for outdoor piping systems and structural applications.

Galvanized seamless steel pipes are commonly used in potable water supply networks, drainage systems, and fire sprinkler pipelines. The corrosion-resistant zinc layer helps maintain internal pipe quality and reduces the risk of leakage, contamination, or pipe failure over time.

For installations where pipe replacement or maintenance is difficult or costly, such as underground pipelines, building infrastructure, or municipal engineering projects, galvanized seamless pipes provide reliable long-term performance and reduced maintenance requirements.

Galvanized seamless steel pipes are suitable for coastal areas, industrial facilities, or environments exposed to salt spray or mild chemical conditions. The zinc coating provides additional protection where ordinary steel pipes would corrode quickly.

When pipelines must handle medium to high pressure fluids or gases while also requiring corrosion protection, galvanized seamless steel pipes offer a balanced combination of mechanical strength and durability.

Galvanized seamless steel pipes are generally not suitable for extremely high-temperature applications, such as certain boiler systems or high-heat industrial processes, because the zinc coating may deteriorate under excessive heat.

In summary, galvanized seamless steel pipes should be selected when corrosion resistance, outdoor durability, and reliable structural strength are critical to the success and longevity of your project.

| Pipe Category | Typical Diameter Range | Standard Length | Estimated Price Range (Per Piece) | Approximate Price Per Foot | Typical Applications |

|---|---|---|---|---|---|

| Small-Diameter Galvanized Steel Pipe | ½″ – 2″ (up to about 3″) | 21 feet (≈6.4 meters) | $30 – $115 | Approximately $2 – $10 per foot | Residential plumbing, sprinkler systems, light structural use, gas and water supply lines |

| Medium-Diameter Galvanized Steel Pipe | 4″ – 6″ | 21 feet (≈6.4 meters) | $690 – $980 | Approximately $33 – $47 per foot | Commercial water systems, municipal drainage, fire protection pipelines, industrial fluid transport |

| Large-Diameter Galvanized Steel Pipe | 8″ and above | 21 feet (≈6.4 meters) | $900+ (Project-specific pricing) | Typically $40+ per foot depending on specifications | Infrastructure projects, large-scale industrial piping, municipal water transmission, structural engineering |

| Supplier / Company | Region | Company Type | Main Strengths |

|---|---|---|---|

| Infra-Metals Co. | North America (USA) | Distributor / Service Center | Wide inventory of carbon and galvanized pipes, processing services such as blasting and priming |

| The Macomb Group | North America (USA) | Industrial Distributor | Supplies multiple schedules (SCH 40, SCH 80, SCH 160), strong supply chain support |

| Totten Tubes | North America (USA) | Steel Tubing Distributor | Large stock range of seamless and galvanized pipes, custom cutting and finishing services |

| United Pipe & Steel (Reliance, Inc.) | North America | Large Distribution Network | Extensive nationwide distribution network, strong inventory availability |

| Continental Steel & Tube Co. | North America (USA) | Metal Distributor | Offers multiple material grades and customized supply solutions |

| Mueller Streamline Co. | North America (USA) | Manufacturer | Long-established pipe manufacturing expertise, strong small-diameter pipe capability |

| Aladdin Steel, LLC | North America (USA) | Distributor | Provides finishing services including coating, cutting, and threading |

| American Piping Products | Global / USA | Manufacturer & Stockholder | Large seamless pipe inventory, international sourcing capability |

| Bri-Steel Manufacturing | North America (Canada) | Manufacturer | Specializes in large-diameter seamless pipes, high-strength materials |

| Van Leeuwen Pipe and Tube Group | Global (Europe / North America / Asia) | Global Distributor | Strong international logistics network, wide product portfolio |

| Interpipe Group | Global (Europe / Export Worldwide) | Manufacturer | Produces carbon steel seamless pipes with global export capability |

Check for a uniform, smooth, and well-adhered coating. High-quality pipes have no peeling, flaking, or exposed steel spots, and may display consistent zinc spangle patterns. Testing thickness with a coating gauge can also ensure compliance with standards.

The service life depends on exposure conditions. In dry indoor environments, galvanized pipes can last 50+ years, while in outdoor or humid environments, a well-applied zinc coating may provide 20–40 years of reliable protection.

Avoid scratching or damaging the coating during handling, use appropriate fittings, ensure proper support and alignment, and prevent contact with incompatible metals or corrosive substances. Proper installation minimizes corrosion and mechanical stress.

Signs include uneven or thin coating, flaking zinc, inconsistent pipe diameter, rough welds or seams (for welded variants), and visible rust shortly after installation. Always request quality certification and inspect the pipe before purchase.

Compared to PVC, HDPE, or stainless steel pipes, galvanized seamless steel pipes provide superior structural strength and moderate corrosion resistance at a competitive cost. They are especially suitable for load-bearing or high-pressure applications.

Select suppliers with verified certifications (ASTM, ISO, EN), traceable quality documentation, positive reviews, and established distribution networks. Reputable suppliers offer consistent material grades, coating quality, and technical support.

Regularly inspect for scratches, dents, or exposed steel. Clean accumulated dirt or debris, ensure proper drainage to avoid standing water, and apply protective coatings or touch-up galvanizing if the zinc layer is damaged.

If you're looking for reliable, corrosion-resistant galvanized seamless steel pipe made from premium materials, meeting stringent production standards, and boasting a long service life, then your search has ended. Dexin specializes in providing tailored, high-quality seamless steel pipe solutions for engineering, construction, and industrial applications, contributing to your project success with consistent performance and highly competitive pricing.

Choose us as your trusted steel pipe supplier, and let our professional products and services safeguard every line of your pipeline. Contact us today for quotes, specifications, and customized solutions!

Your Name*

Your Email*