When it comes to industrial piping solutions, two main contenders dominate the market — seamless pipes and welded pipes. Choosing between them is not just about price; it’s about performance, application, and long-term value. This guide walks you through definitions, key differences, cost factors, inspection tips, and a B2B-focused decision framework so you (or your procurement team) can pick the right product with confidence.

If you’ve ever held a piece of steel pipe and wondered why some have a visible seam while others look perfectly smooth, you’ve already spotted the biggest clue. A seamless pipe is exactly what it sounds like — a steel pipe with no welded seam along its length. Instead of being rolled and joined from a flat sheet (like a welded pipe), a seamless pipe is made by piercing a solid billet of steel and then elongating it into a hollow tube. This production method eliminates the weld line entirely, giving it a uniform structure from end to end.

From a technical point of view, the absence of a seam means fewer weak points. That’s why, in the seamless pipe vs welded pipe debate, seamless options are often seen as the stronger choice, especially for high-pressure, high-temperature, or critical applications like oil & gas transmission, chemical processing, or power generation.

Imagine you’re building a high-pressure boiler system. Would you rather trust a pipe with a stitched seam running along its length, or a solid tube formed in one continuous piece? That’s why engineers often ask: Which is stronger, seamless or welded pipe? — and the answer, in most demanding scenarios, leans toward seamless.

For product-specific options, check our Seamless Line Pipe range or learn about specialized grades such as ASTM A333 Gr.6 Low-Temp Seamless Steel Pipe.

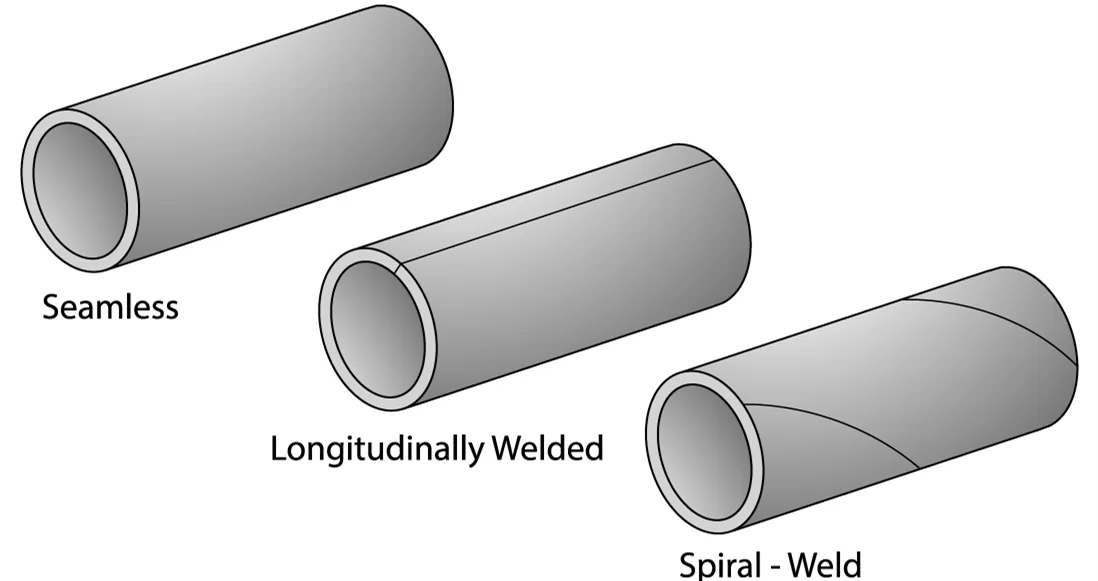

While a seamless pipe starts life as a solid billet, a welded pipe begins as a flat steel plate or strip. The plate is rolled into a cylindrical shape and then joined along its length using a welding process. That welded joint — known as the seam — is the most visible difference in the seamless pipe vs welded pipe discussion.

Welded pipes are versatile, cost-effective, and widely used in construction, water transportation, low- to medium-pressure fluid systems, and many structural applications. If your project doesn’t involve extreme pressure or temperature, a welded pipe might be the wiser, more economical choice.

One of the most common types is the ERW pipe (Electric Resistance Welded pipe). ERW pipes are made by rolling a steel coil into a tube and then applying high-frequency electric resistance to fuse the edges together. This process produces a consistent weld that, with modern equipment, can be nearly as strong as the base material. ERW pipes are popular for their precision, uniform wall thickness, and cost efficiency — ideal for pipelines, scaffolding, and mechanical structures.

Other welded methods include:

Explore welded solutions and ERW options in our products catalog or request a quote for custom sizes.

For engineers, procurement managers, and project planners, it’s not just about how pipes are made — it’s about what the differences mean for performance, cost, and risk. The table below summarizes the core contrasts:

| Feature | Seamless Pipe | Welded Pipe (Including ERW) |

|---|---|---|

| Manufacturing Process | Made by piercing and elongating a solid billet; no weld seam. | Made by rolling plate/coil and welding the seam (ERW, LSAW, SSAW methods). |

| Strength | Generally stronger with uniform structure; better for extreme conditions. | High-quality ERW pipe offers good strength, but seam area can be a weak point in critical applications. |

| Pressure & Temperature Resistance | Excellent for high-pressure and high-temperature environments. | Suitable for moderate pressure and temperature ranges. |

| Size Range | Typically smaller diameters; limited by manufacturing process. | Available in larger diameters and longer lengths. |

| Cost | More expensive due to complex production and material usage. | More cost-effective and faster to produce. |

| Surface Finish & Precision | Smooth, seamless surface; may require extra finishing for precision work. | Excellent dimensional accuracy and uniform wall thickness. |

| Common Applications | Oil & gas, power plants, chemical processing, aerospace, heavy industry. | Water pipelines, construction, scaffolding, structural uses, general industrial applications. |

Seamless pipe: Produced by piercing a solid billet, then elongating it into a hollow tube. No weld seam exists.

Welded pipe (including ERW): Made by rolling a flat plate or coil into a cylinder and joining the edges with a welding process. The weld line is the most distinct feature.

Why it matters: The absence of a seam in seamless pipes eliminates a potential weak point, which can be critical in high-pressure or high-stress environments.

This is where the question "Which is stronger, seamless or welded pipe?" comes into play.

Seamless pipe: Generally stronger and more resistant to pressure because of its uniform structure.

Welded pipe: Modern ERW manufacturing has narrowed the strength gap significantly, but in ultra-critical applications, the weld area remains a consideration.

Seamless: Handles higher pressures and temperatures without failure — the default choice for pipelines, boilers, and heavy industry.

Welded: Suitable for moderate pressures and temperatures commonly found in building services and general industrial systems.

Seamless: Best for small-to-medium diameters where structural integrity is prioritized.

Welded: More flexible for large diameters and very long lengths (LSAW, SSAW).

Seamless: Premium price due to complex processing and lower material yield.

Welded (ERW): More economical for large-volume and large-size orders.

Seamless: Smooth, uniform surface that often requires less finishing in certain applications.

Welded: Excellent dimensional control — ERW pipes are known for consistent wall thickness and precision.

Bottom line: Seamless pipes are the champions of high-pressure, high-temperature, and mission-critical environments. Welded pipes — particularly modern ERW pipes — win in affordability, size flexibility, and quick delivery. The "better" choice depends entirely on your project's technical demands, safety requirements, and budget.

Cost is a primary deciding factor for many procurement teams. Here’s a clear breakdown so you can evaluate total cost of ownership, not just purchase price.

| Comparison Criteria | Seamless Pipe | Welded Pipe (including ERW) |

|---|---|---|

| Production Costs | More complex manufacturing process — piercing and elongating a solid billet requires specialized equipment, higher energy consumption, and more material waste, leading to higher production costs. | Formed by rolling a flat plate or coil and welding into shape; faster, more material-efficient, and ERW production lines can operate continuously, reducing labor and energy costs per unit. |

| Material Utilization | Consumes more raw material during machining and shaping, resulting in a higher per-meter price. | Better material yield with minimal waste, making it more cost-effective for high-volume orders. |

| Size & Customization Impact | Small- to medium-diameter seamless pipes can be competitive, but large-diameter seamless options are significantly more expensive. | Large-diameter LSAW or SSAW pipes can be produced at a fraction of the cost of seamless equivalents. |

| Price Range Overview | Higher — often 20%–40% more than welded. Price drivers: complex production, higher labor costs, lower material yield. | Lower — more budget-friendly. Price drivers: high production speed, efficient material use, suitable for large-scale manufacturing. |

| Long-Term Cost Considerations | In high-pressure, safety-critical applications, durability can prevent costly downtime, repairs, and safety incidents — making it a worthwhile investment. | For non-critical uses, high-quality ERW pipes can deliver excellent performance without significantly increasing project costs. |

| Recommended Use | Best for projects requiring maximum performance under extreme conditions. | Ideal for general industrial, structural, and moderate-pressure systems, offering excellent cost-effectiveness. |

To learn more about price trends and buying strategies, see our Seamless Pipe Prices: Cost Analysis and Buying Guide.

Here’s a practical table to help you identify welded vs seamless pipes by sight, marking, and simple checks.

| Feature | Welded Pipe | Seamless Pipe |

|---|---|---|

| Weld seam visible? | Yes, along the length | No |

| Internal weld bead | Often present | None |

| Diameter / wall uniformity | Very consistent | Slightly variable |

| Markings | "ERW", "LSAW", "SSAW" | "SMLS" |

| Manufacturing process | Rolled plate/coil + welding | Pierced & elongated billet |

Choosing the right pipe is a balancing act between technical requirements and budget. Here’s a quick decision framework for B2B buyers:

High pressure or high temperature? Go for seamless pipes. With no weld seam, they have a uniform structure and superior resistance to extreme conditions.

Moderate pressure and temperature? Welded pipes (including ERW) can handle these applications well — and at a much lower cost.

Need small- to medium-diameter pipes with maximum strength? Seamless is the safer bet. Need large-diameter or extra-long pipes? Welded pipes offer more flexibility and better pricing.

Seamless pipes typically cost 20%–40% more than welded equivalents but can save money in the long run by reducing downtime in critical systems. Welded pipes are more cost-efficient for bulk orders and general-purpose use.

Certain industries (oil & gas, nuclear, chemical) may require seamless pipes to meet strict safety standards. For less hazardous sectors (construction, water supply), ERW pipes often meet necessary certifications at a lower cost.

Seamless production can take longer for custom sizes. Welded manufacturing — especially ERW — can operate continuously for faster turnaround.

| Factor | Choose Seamless If… | Choose Welded If… |

|---|---|---|

| Pressure / Temperature | Extreme conditions | Moderate conditions |

| Size | Small–medium diameter | Large diameter / long lengths |

| Budget | Premium available | Cost-sensitive |

| Delivery | Flexible | Short lead time needed |

Not always — but in demanding environments, yes. Seamless pipes lack a weld seam (a potential weak point), so they generally perform better under extreme pressure and temperature. However, modern ERW pipe manufacturing has improved weld quality significantly; in many moderate-pressure applications, a welded pipe can be just as durable.

It depends on the application. For high-pressure, high-temperature or safety-critical systems (like oil & gas pipelines and boiler tubes) seamless is typically preferred. For less demanding uses — water distribution, structural scaffolding, and general industry — welded pipes (including ERW) can replace seamless pipes and save cost.

Typically, seamless pipes are stronger in extreme service because they have no seam. That said, high-quality ERW pipes meet many industrial strength requirements and are often fully adequate for non-critical systems when produced and inspected to the right standards.

Neither is universally better — it’s about fit-for-purpose. Seamless pipes excel in critical, high-risk environments. ERW pipes excel in cost efficiency, size flexibility, and speed of delivery. Choose based on application, not on a blanket “better” label.

In the seamless pipe vs welded pipe conversation, there is no absolute winner — only the right choice for the right job. Seamless pipes offer superior structural integrity for high-pressure, high-temperature, and safety-critical projects. Welded pipes, including ERW, provide cost efficiency, size flexibility, and fast production for general industrial uses.

When deciding, look beyond the unit price. Consider operating conditions, compliance requirements, inspection standards, and total cost of ownership. Ask: “Which pipe is stronger for my specific application?” — because that’s the question that leads to the right procurement decision.

As a manufacturer and supplier with expertise in both seamless and welded pipe solutions, we match products to project specs and budgets every day. If you’re evaluating material grades, comparing quotes, or planning a pipeline project, our engineering and procurement team can help guide your choice.

What Is Difference Between Seamless and Welded Pipe?

Seamless vs Welded Pipes: A Comprehensive Guide for the Oil & Gas Industry

Welded vs. Seamless Tubing: Choosing Stainless Steel Tube

Steel Pipes: Choosing Between Seamless and Welded

Which Is Better Between Seamless Vs Welded Pipe?

Difference Between Seamless and Welded Pipe

Your Name*

Your Email*